What does it mean to design with hardwood?

Designing with hardwood: the crucial role of screws

Designing with hardwood is about more than just visual appeal. It is a technical decision that directly affects mechanical strength, material density, long-term durability and screw performance.

Failure to properly assess the use of hardwood in construction can lead to serious issues. Standard screws – especially untreated steel or coarse-threaded screws – struggle to penetrate high-density species such as beech, oak or ash.

The risk with standard screws? Screw failure or unreliable fastening.

Denser, more stable, and often local: hardwoods play a central role in many architectural contexts, from North American mass timber to traditional European roofing. And precisely because of their compact cellular structure, they exert greater stress on fastening devices.

Structural timber screws must therefore be selected – and tested – according to the wood species. This practical need is precisely what led to the development of the Rothoblaas range for hardwood: screws engineered for smooth penetration, strong anchoring and long-term durability, even in highly acidic conditions or when exposed to corrosive tannins.

What is hardwood: technical features and strength

The term hardwood refers not just to surface hardness, but to slow-growing broadleaf tree species with a denser wood structure. The volume being equal, they offer greater resistance to compression, bending and shear loads.

Their complexity is similarly reflected throughout the supply chain – from logging through to transport, more powerful equipment and machinery are needed. The logs are heavier and thus require more precise handling during both felling and movement.

Their higher density also impacts processing in sawmills and carpentry, where cutting, planing and drilling require stronger tools, high-performance machinery and special-purpose blades.

Density of main European hardwoods (in kg/m³):

Oak: 700–900

Beech: 720–800

Ash: 680–750

For comparison, Norway spruce has a density of about 450 kg/m³.

These values explain why hardwood better withstands loads, but also presents operational challenges when it comes to fastening, while the screw needs to withstand greater torque during insertion.

Timber density and screw performance: what the technical literature says

Timber density is a key factor when designing structural connections.

In the range above 700 kg/m³ – which includes beech, oak, iroko and many tropical species – the use of standard screws leads to issues such as deformation or loss of holding power. That’s why Rothoblaas has developed a range of structural screws for hardwood, designed to ensure smooth penetration, controlled torque and secure mechanical fastening, even in wood types exceeding 1000 kg/m³.

The result: A connecting system that reduces the need for pre-drilling and delivers consistent performance over time, even in the hardest wood types.

Where hardwoods are used today

Europe

Central Italy, the Balkans, Austria, Switzerland: oak, chestnut and beech are commonly used in roofs, pergolas and hybrid structures. The materials are often locally sourced, processed through regional supply chains.

Northern Europe

Sweden, Finland and Germany also use them in residential homes and for visible structural elements.

North America

In the United States, species such as red or white oak and ash are used in "oak frame housing".

Asia

In Indonesia, the Philippines, India and Vietnam, dense tropical species are often used for high-end projects or those involving structural elements made from reclaimed hardwood.

Why hardwood needs special-purpose screws

Fastening hardwood presents a number of technical challenges. Its high density, for example, makes it more difficult to insert screws and requires higher torque, increasing the risk of screw failure or timber splitting. Standard threads are not designed to withstand these conditions, leading to complications such as the need for pre-drilling and a gradual loss of holding power. Additionally, many hardwoods have an acidic pH, which accelerates the corrosion of traditional screws if they are not properly treated.

For all these reasons, Rothoblaas has developed a range of screws specifically designed for hardwood, featuring optimised shapes, reinforced steels (AISI 410) and tested performance across various wood species.

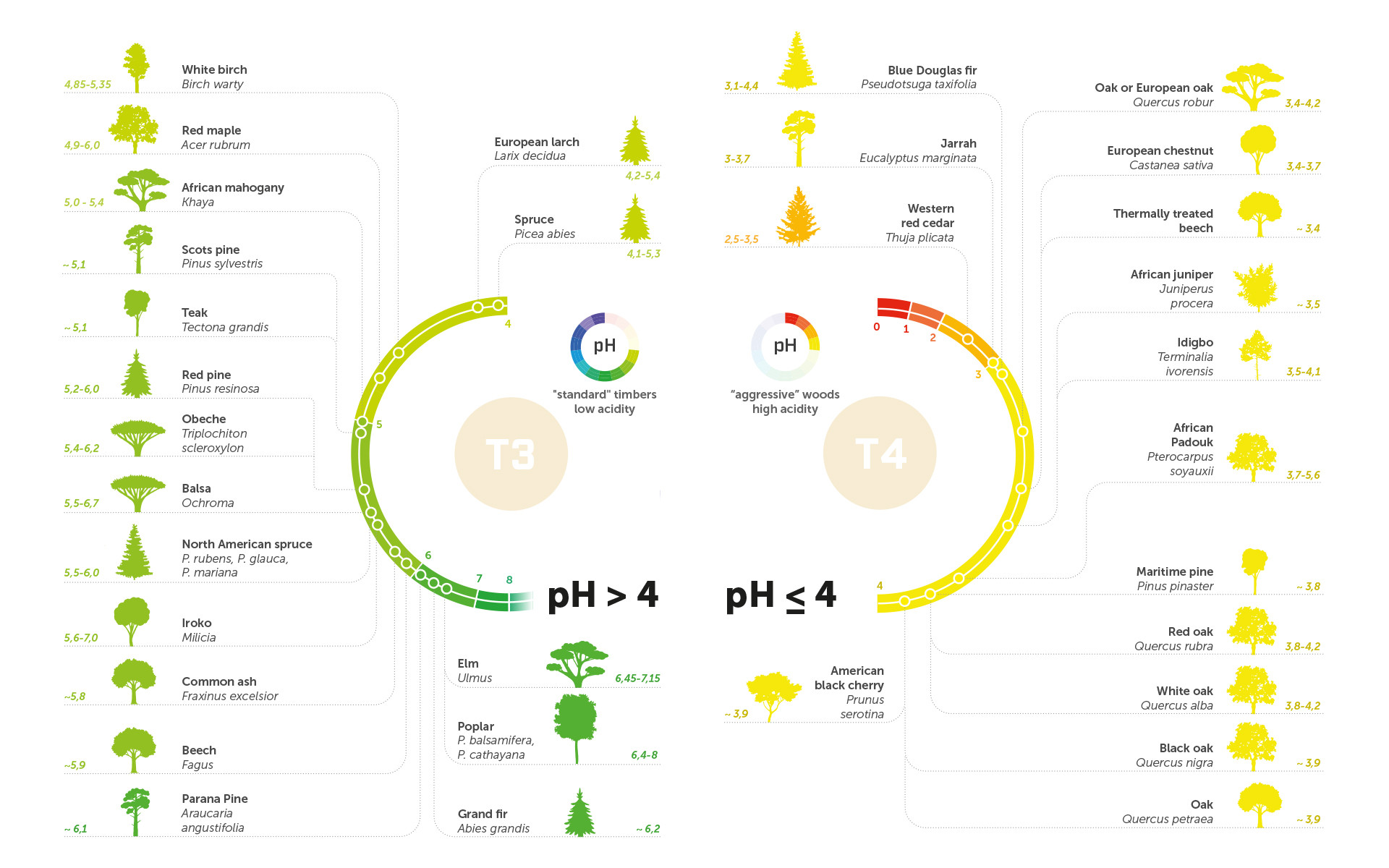

The role of pH in hardwoods: a commonly overlooked chemical factor

Many hardwoods, particularly beech, oak and several tropical species, have a pH below 4. This indicates strong natural acidity, caused by tannic acids, phenols and other organic compounds.

A pH less than 4 can accelerate galvanic corrosion if standard screws are not properly treated or coated. This phenomenon becomes especially relevant in extremely humid environments (for example, in service class 3), where the wood’s acidity can compromise the durability of the fasteners.

Rothoblaas screws for hardwood are designed for use in dry conditions, where the wood’s acidity does not affect corrosion. In humid environments or applications demanding higher resistance to corrosion, such as those involving acidic hardwoods, stainless steel screws in AISI 410 (SHS AISI 410) are the ideal choice, striking an excellent balance between corrosion resistance and mechanical performance. It is important, however, to avoid environments with chloride sources, such as marine settings.

Rothoblaas screws for hardwood

HBS HARDWOOD

Carpentry screw with cylindrical head, precision-ground tip, high-penetration thread. Optimised for direct insertion without pre-drilling in wood types up to 780 kg/m³.

Applications: beans, purlins, visible load-bearing joints.

View product sheet

VGZ HARDWOOD

Structural screw with countersunk head, double thread and high axial holding power. Ideal for shear connections on loaded sections.

Applications: main beams, concealed joints, wall connections.

View product sheet

LBS HARDWOOD / LBS HARDWOOD EVO

The LBS HARDWOOD and LBS HARDWOOD EVO screws are designed to ensure high performance even in high-density hardwoods such as beech LVL (>1000 kg/m³). Both feature advanced geometries and latest-generation technologies for optimal fastening, but the EVO version offers improved performance in timber-to-metal applications, featuring a more aggressive tip and optimised thread for faster insertion and superior mechanical hold.

LBS HARDWOOD

ROUND HEAD SCREW FOR PLATES ON HARDWOOD

The LBS HARDWOOD screw is specifically designed for use in hardwood, thanks to a uniquely profiled tip for smooth insertion in high-density timber. ETA-11/0030 certified, it allows for direct installation without pre-drilling in woods with a density of up to 800 kg/m³. It is approved for structural applications in any direction relative to the grain, making it suitable for a wide range of fastening configurations.

Made of bright zinc plated carbon steel, it is ideal for use in solid timber, glulam, timber-based panels (such as CLT, LVL, Beech LVL) and high-density hardwoods such as beech, oak, cypress, ash, eucalyptus and bamboo. Testing and certification have confirmed its strength even in high-density timber, such as beech laminated veneer lumber (LVL).

Applications: steel plates, hybrid systems, constructions with engineered elements, high-density timber.

LBS HARDWOOD

LBS HARDWOOD EVO

ROUND HEAD SCREW FOR PLATES ON HARDWOOD

The LBS HARDWOOD EVO is a screw designed for hardwood applications, featuring a C4 EVO coating that provides atmospheric corrosion resistance certified by the Research Institutes of Sweden - RISE. This coating is particularly suitable for timber with a pH above 4, such as spruce, larch and pine. The C4 EVO coating ensures excellent resistance even in exposed environments and delivers high performance in moderate weather conditions.

Like the “standard” version, the LBS HARDWOOD EVO screw features a uniquely profiled tip, allowing direct screwing into high-density timber without the need for pre-drilling. ETA-11/0030 certification confirms its reliability for structural applications subjected to stress in any direction relative to the wood grain.

Applications: steel plates, hybrid systems, constructions with engineered elements, timber-to-steel joints, solid timber and LVL structures.

SHS AISI 410

The properties of the AISI 410 martensitic stainless steel make this screw ideal for outdoor use, especially in hardwoods exposed to humid conditions. Its compact head and high-performance thread ensure precise insertion even in thinner timber sections.

Applications: small outdoor structures, works in humidity-exposed environments where corrosion resistance is crucial.

Why use them in softwoods, too?

A common misconception is that hardwood screws are oversized for more common wood types. In actual fact:

they offer superior mechanical performance, meaning fewer screws are needed to achieve the same strength;

they speed up installation (smooth insertion, no failure).

The result: fewer pieces, less waste, more efficient construction sites.

An example of hardwood architecture using HBSH and LBSH

Begawan Biji, a restaurant in Payangan (Bali) surrounded by lush forest and a permaculture garden, was built using tropical ironwood, secured using just 750 fasteners, including LOCKT, HBSH and LBSH.

Screws for hardwood, even when the wood isn’t hard

Investing in high-performance screws isn’t limited to working with oak or teak, two of the most commonly used hardwoods in timber construction. It is essential wherever structural reliability, durability and on-site efficiency are key priorities.

That’s why Rothoblaas provides specific strength data for each wood species, along with comparative testing between hardwoods and softwoods.

Find the screw most suited to your project. Read more

Technical sources

EN 1995-1-1 Eurocode 5, design of timber structures

Requires verification of mechanical compatibility between fasteners and substrates based on the wood species, focusing in particular on strengths and loads.

ETA – European Technical Assessment, Guidelines for screw certification

Screws must be tested in high-density species to verify their resistance to insertion, pull-out strength and resistance to shear loads. Performance in hardwoods can differ by up to 40% compared to softwoods.

EN 14592, fasteners for timber structures

Includes guidelines on corrosion, durability requirements and testing under aggressive conditions (including low pH and exposure to tannins).

All rights reserved

Technical Details

- Country:

- Any

- Produkty:

- HBS HARDWOOD LBS HARDWOOD LBS HARDWOOD EVO SHS AISI410 VGZ HARDWOOD