Timber Frame, Steel Frame and Light Timber Frame: What they are

Why prefabricated construction systems are increasingly popular

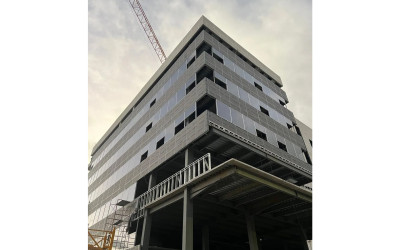

Frame prefabrication is shifting the centre of gravity from building sites to factories. Timber Frame, Light Timber Frame and Steel Frame offer shorter construction and installation times, greater control over production costs and more consistent quality thanks to proven industrial processes.

In English-speaking markets, light frame has been the benchmark solution for decades, but throughout the entire former Commonwealth, the United States, Canada and Australia, for example, dedicated regulations and production chains are developing at a strong pace. In Europe, the trend is much the same, driven by the obligation to reduce energy consumption and emissions, combined with the need to invest in efficient construction sites with reliable delivery times.

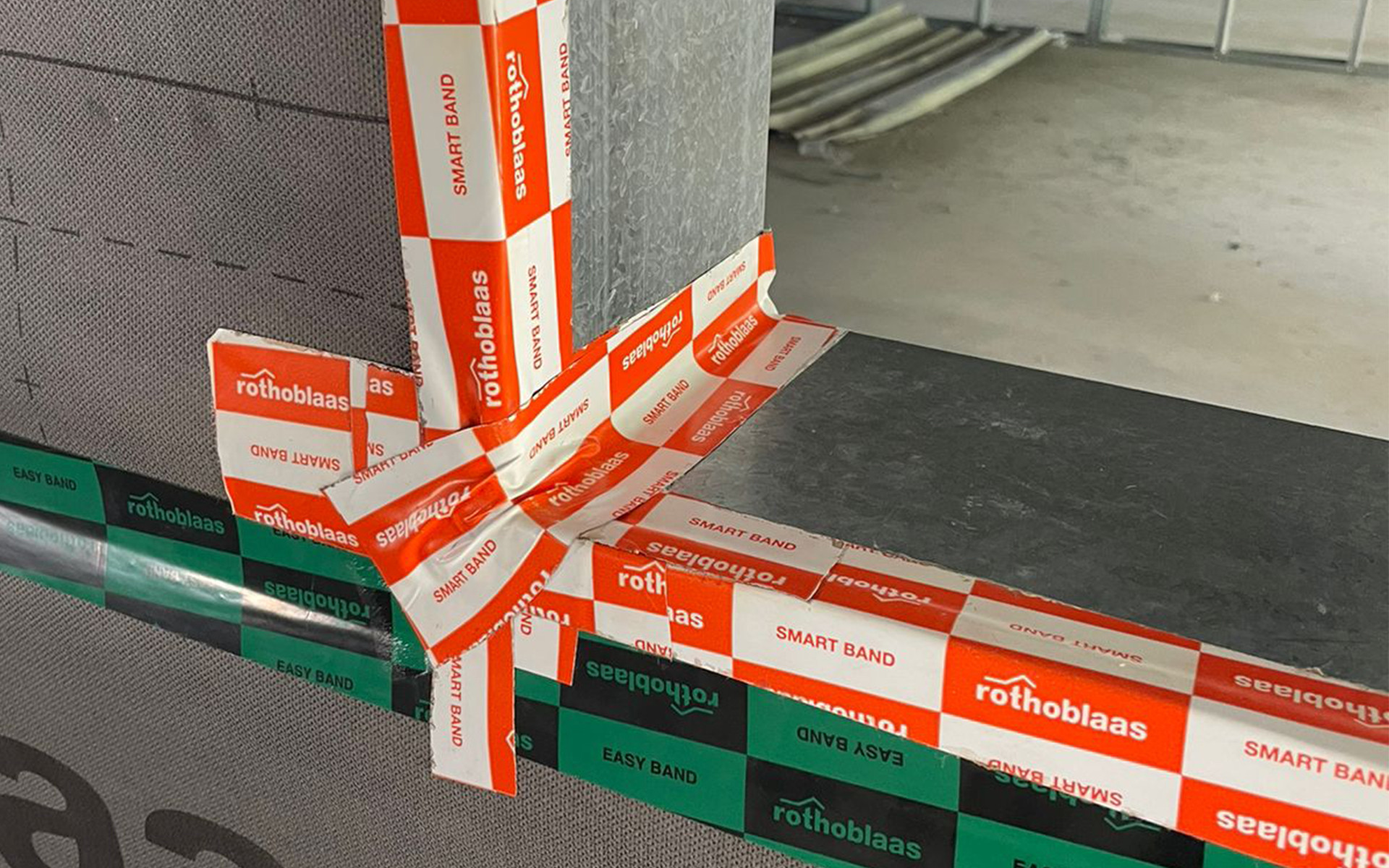

The real difference lies in the ability to rely on integrated technical solutions: vapour barriers, soundproofing, fastening systems, airtightness and fire protection can be pre-installed during production. The result is a faster, more modular system.

What is Timber Frame construction?

Timber Frame is a construction system in which the load-bearing structure consists of a timber frame, prefabricated in the factory and assembled on site.

It can be used for single-family homes, terraced houses and, increasingly, for multi-storey buildings thanks to new engineering solutions.

Timber Frame uses timber uprights and beams that define the load-bearing structure. The spaces within the frame are filled with insulating materials, while structural panels and claddings complete the build-up, often already equipped in the factory with internal and external protection layers and, in some cases, even windows and service systems.

When well designed in all its components, Timber Frame construction ensures excellent energy performance, optimal integration of service systems and design flexibility.

It is a timber frame construction system produced in the factory and assembled on site with reduced tolerances, enabling:

Optimal thermal performance thanks to continuous insulation

Controlled acoustic behaviour with targeted layers

Simplified integration of service systems and windows during production

In seismic contexts, well-designed Timber Framing offers ductility and dissipative capacity. In humid climates, protection against infiltration is achieved through membranes and precise construction details.

Fire performance, often underestimated, must instead be addressed at the design stage with certified solutions to ensure resistance, such as those in the dedicated section on our website.

How much does a Timber Frame house cost?

The average cost in Europe ranges from 1,800 to 2,400 €/m² depending on the level of prefabrication and the included finishes.

What are Steel Frame buildings?

Steel frame is a construction system in which the load-bearing structure consists of light steel profiles, assembled dry.

This technique is similar to Timber Frame in terms of prefabrication and assembly, but makes use of the mechanical properties of steel to achieve slimmer, lighter elements.

Widely used for commercial buildings, additional storeys, extensions and also in light residential construction, Steel Framing stands out for its precision, lightness and durability.

Steel Frame uses thin, zinc-plated steel profiles manufactured in the factory and connected on site without welding. Compared with timber, steel offers:

Dimensional stability in all environmental conditions

The possibility of creating slimmer elements with the same strength

Quick assembly even in refined spaces

Reduced structural weight, helpful in additional storeys

However, Steel Framing requires careful thermal and acoustic design: the conductivity of steel can create thermal bridges if not interrupted by continuous insulating layers. Protection against corrosion is also essential, particularly in marine or aggressive industrial environments.

We have covered this topic in detail in a dedicated article.

What makes Steel Frame constructions potentially more cost-effective?

This type of construction shortens on-site building time and centralises much of the work in the factory.

In Steel Framing, the light weight of the profiles makes it possible to move large quantities of materials quickly and with minimal equipment. Assembly is performed using standardised connections, which cuts down on the training time needed for workers and reduces the amount of equipment required.

The result is a compressed construction cycle, with fewer billable hours on site and greater predictability of final costs. This is particularly evident in serial projects such as residential complexes or modular extensions.

Light Timber Frame: What are the most common types?

Light Timber Frame structures are configurations of lightweight timber frames, which can be adapted according to the project and the desired level of prefabrication. It is a construction system which, contrary to what one might assume, is not based on standardised prefabrication but rather on close attention to detail and to the most varied architectural requirements.

The frame is usually made of solid timber, finger-jointed timber or OSB, among other timber-based materials. Light Timber Frame is not a single construction method, but rather a set of approaches: Platform frame, Balloon frame, Semi-balloon and Truss-framed.

The effectiveness of the system depends on consistency between the final working design, production and attention to detail during installation – mistakes at any of these stages would inevitably affect the final quality.

We have created a dedicated guide: https://www.rothoblaas.com/catalogues-rothoblaas/timber-frame

Are Timber Frame and Steel Frame less expensive?

Yes. When considering the cost across the entire lifecycle of the building site, Steel Frame and Timber Frame constructions are on average less costly.

Prefabrication makes it possible to install air- and watertight layers, acoustic profiles, service systems and sealing solutions directly in the factory, reducing on-site work to a minimum. This means fewer days on site, lower risks due to weather conditions and fewer extra costs.

Moreover, pre-sealed and protected components are less prone to damage during installation. The impact on maintenance is also positive: protected structures assembled quickly tend to maintain their designed performance for longer.

Rothoblaas brings prefabrication to the Offsite Expo

Given the potential and growing adoption of these construction systems, Rothoblaas has dedicated increasing effort to developing tailored solutions. To make these available – not only through online resources but also in person – we will be presenting them at the Offsite Expo in Coventry, UK (16–17 September 2025), together with:

Technical guides dedicated to Timber Frame and Steel Frame;

Exhibits showcasing examples of connections, membranes and certified solutions for frame prefabrication

Direct consultancy sessions with specialised technicians

The aim is to provide professionals with the knowledge and tools they need to adopt Steel Framing and Timber Framing in an increasing number of projects.

Looking ahead: Framing as the standard

Shifting most of the work to the factory and reducing on-site uncertainties is an inevitable step. Timber Frame, Light Timber Frame and Steel Frame are no longer a niche, but proven solutions for faster, more precise, more sustainable construction.

And when it comes to bringing the elements to the construction site, there’s an entire dedicated section.

Choose the right products for these systems in the dedicated Timber Frame and Steel Frame guides, or come and meet us at the Offsite Expo to see first-hand everything that’s new.

All rights reserved

Technical Details

- Country:

- Any

- Produkty:

- EASY BAND SMART BAND WASP